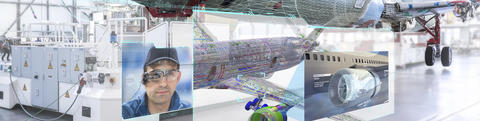

To bring advanced aerospace concepts to life, future materials must be more durable, lightweight and cost-effective than ever before. At Airbus, we are exploring the potential of tomorrow’s materials with a focus on environmental impact, multi-functionality and digitalisation.

Unlocking the potential of tomorrow’s materials

Over the last decades, the aerospace industry has pioneered a wide range of materials to support the development of advanced aerospace concepts. These materials include metals, composites, ceramics, coatings and other associated processes.

Today, future materials development at Airbus focuses on the following priorities:

- Sustainability: Minimising resource use and optimising waste disposal of materials can help mitigate an aerospace product’s end-to-end footprint across its global lifecycle, improving its overall environmental impact.

- Multi-functionality: Integrating multiple functions into materials can help reduce lead times during manufacturing and enable predictive maintenance. Further multi-functionality will enable advanced concepts and improve mission performance.

- Digitalisation: Digital modelling and virtual experiments can optimise the performance testing of materials and help reduce their development lead times, thereby accelerating time to market. Designing materials from the molecular structure will accelerate the application of future materials.

Research areas

Natural fibres

These fibres can be obtained from animals, plants or minerals. Due to their lightweight and high-strength properties, they could be used in bio-composites for a variety of applications, including secondary, non-critical aircraft structures. Research areas include basalt fibres, spider silk, bamboo, flax and their processing routines.

Biomass carbon fibre

These fibres are created by carbonising precursors obtained from biomass derived from raw materials. Their use in bio-composites could result in composite materials that provide a viable alternative to carbon fibres obtained from oil-based precursors. Research areas include algae.

Bio-sourced resins

These resins derive some or all of their constituent monomers from biological sources (i.e. sugar cane, lignin). Their use could provide an alternative to phenolics in aircraft. Research areas include furan, epoxy and polyamide.

Latest news